ABOUT CARBON FIBER

You name it and it can be made from carbon fiber!

Lightweight. Durable. Carbon fiber is a low-density material with a very high strength-to-weight ratio. This means that carbon fiber is incredibly tough and light, five times stronger than steel and 43% lighter than aluminum, making it perfect for manufacturing applications.

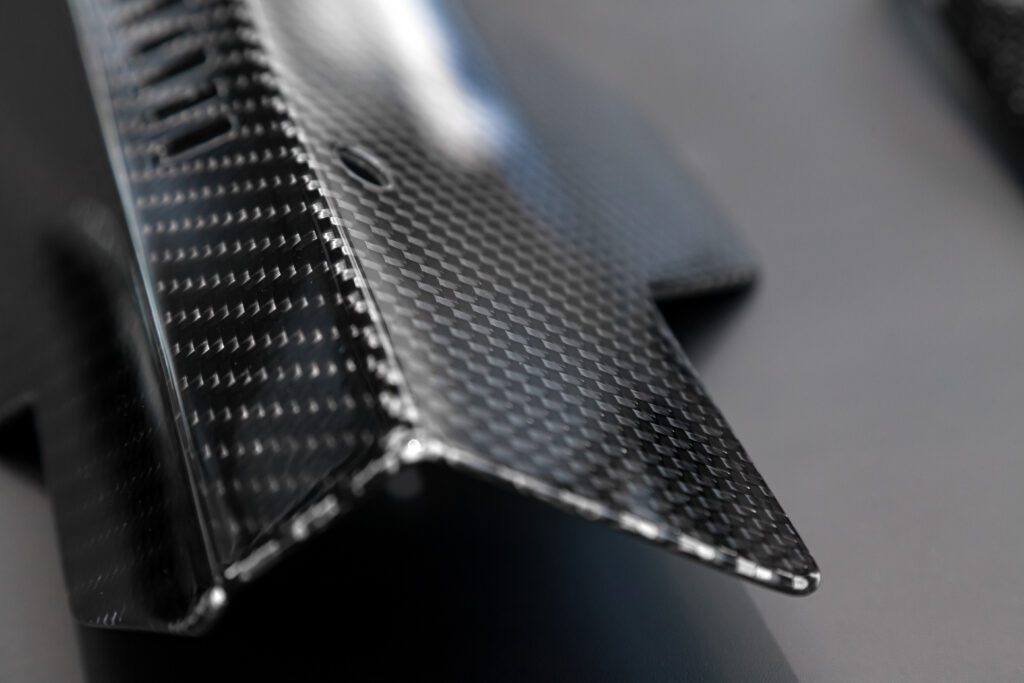

At the core of carbon fiber, and its praised properties is its unique structure: carbon atoms are bonded together to form crystals that are then aligned parallel to the long axis of the organic fiber. Mimicking that of yarn, these fibers are made up of thousands of extremely thin carbon strands that are interwoven together. This unique composition and production largely contribute to its indispensable properties!

From lightweight versatility to durability, energy absorption, and sleek appearance, carbon fiber offers numerous manufacturing benefits and is ideal for virtually anything.

4X The Strength of Steel

Strength-to-weight ratio:

Carbon fiber is stronger than steel when comparing strength per unit of weight.

Tensile strength:

Carbon fiber can have a tensile strength of up to 6,000 MPa, while steel's tensile strength ranges from 400 to 1,200 MPa.

5X Lighter Than Steel

Density:

Carbon fiber has a density of around 1.6g/cm³ while steel has a density of around 7.85 g/cm³.

Applications:

Density:

Carbon fiber has a density of around 1.6g/cm³ while steel has a density of around 7.85 g/cm³.

Extremely beneficial in applications where weight reduction is crucial, like aerospace, UAV, lightweight outdoor gear, high-performance vehicles, and much more.

3X More Stiff Than Aluminum

How is carbon fiber's stiffness measured?

-

The stiffness of a material is measured by its modulus of elasticity.

-

This is calculated by dividing the change in stress by the change in strain.

-

The modulus of carbon fiber can range from 150–760 GPa, depending on the manufacturing process.

Why is carbon fiber so stiff?

-

Carbon fiber's stiffness and strength come from its crystalline structure.

-

It's made from carbon, a naturally occurring element.

It's used to make lightweight, high-strength composite parts.

How is carbon fiber's stiffness measured?

-

The stiffness of a material is measured by its modulus of elasticity.

-

This is calculated by dividing the change in stress by the change in strain.

-

The modulus of carbon fiber can range from 150–760 GPa, depending on the manufacturing process.

Why is carbon fiber so stiff?

-

Carbon fiber's stiffness and strength come from its crystalline structure.

-

It's made from carbon, a naturally occurring element.

It's used to make lightweight, high-strength composite parts.

High Fatigue and Corrosion Resistence

High fatigue resistance:

-

Carbon fiber composites can withstand repeated loading and unloading cycles without experiencing significant damage, making them ideal for applications with cyclic loading or vibration.

-

The fiber orientation of carbon fibers within the composite significantly affects its fatigue resistance.

Corrosion resistant:

Due to its inherent chemical composition, carbon fiber is highly resistant to corrosion and does not rust like metals, making it suitable for outdoor use.

Application:

This combination of properties allows carbon fiber to be used in various applications like aerospace, automotive parts, sports equipment, and structural components where both strength and resistance to environmental factors are crucial.

High fatigue resistance:

-

Carbon fiber composites can withstand repeated loading and unloading cycles without experiencing significant damage, making them ideal for applications with cyclic loading or vibration.

-

The fiber orientation of carbon fibers within the composite significantly affects its fatigue resistance.

Corrosion resistant:

Due to its inherent chemical composition, carbon fiber is highly resistant to corrosion and does not rust like metals, making it suitable for outdoor use.

Application:

This combination of properties allows carbon fiber to be used in various applications like aerospace, automotive parts, sports equipment, and structural components where both strength and resistance to environmental factors are crucial.

WHAT CAN BE MADE WITH CARBON FIBER?

Drones

Ankle foot orthotics (AFOs)

Electrical parts

Medical accessories

Windmills/solar accessories

Pickleball paddles

Backpack frames

Canoe paddles

Sports equipment

and more.

Lamborghini "Forged Composite" Technology

Learn more about the development of suspension control arms and cost/cycle time reduction with respect to forged composite.

Thermoplastic Composite

Learn more about the features, performance, and benefits of thermoplastic composite.

What is a Forged Composite?

Learn about the advantages of forged composite and its potential useful applications.

Rod And Aluminum Alloys With Carbon Fiber

Read a 2014 analysis of connecting rod with aluminum alloys and carbon fiber.