Custom Carbon Fiber & Composite Manufacturing

We make carbon fiber parts. Built for performance.

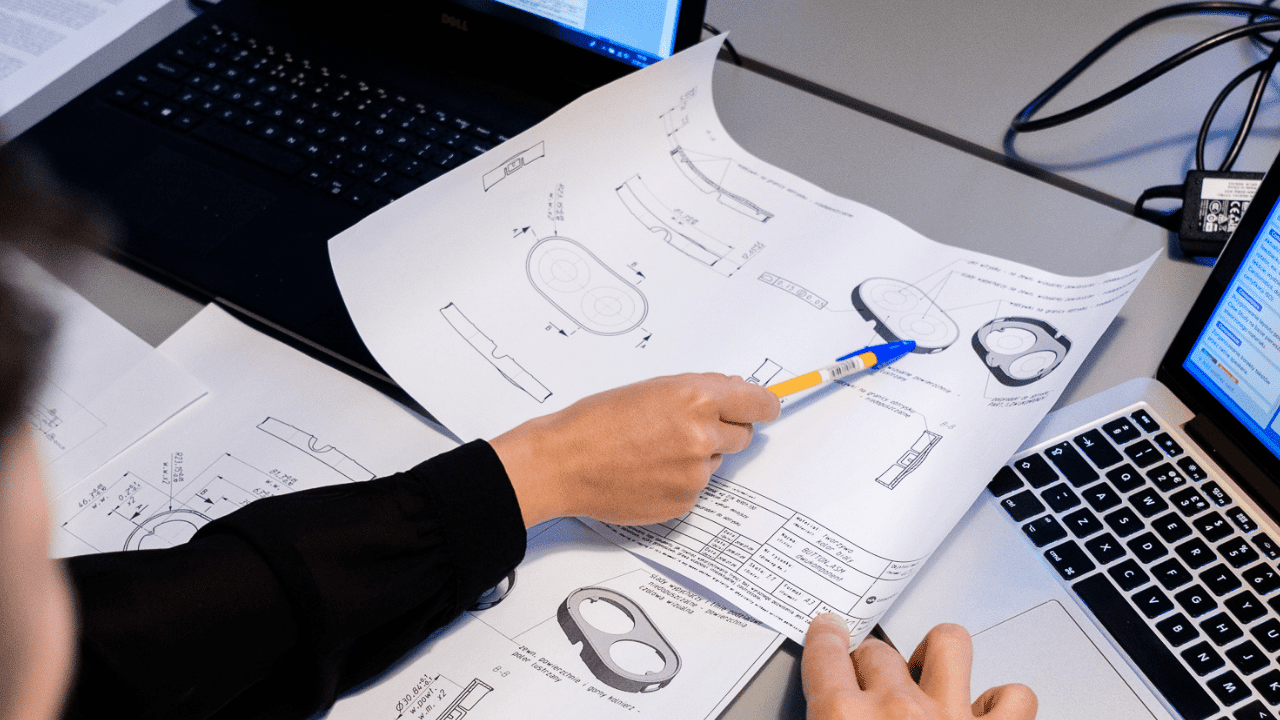

At Southwest Composite Works, we partner with companies across a wide range of industries to elevate their products with precisely engineered, machined, and molded carbon fiber components. Our proprietary, American-made process delivers lightweight, high-performance parts built for strength, precision, and reliability. From prototyping to full-scale production, we design and manufacture composite parts and tooling with efficiency and purpose. Whether you need specialized development or complete manufacturing support, our team delivers dependable, U.S. made solutions in carbon fiber, advanced plastics, aluminum, and more, engineered to perform where quality matters most.

From Prototype to Production. Precision at Every Step.

OUR SERVICES

WE ARE AS DIVERSE AS CARBON FIBER

At Southwest Composite Works, diversity in the industries we serve and the scope of our work set us apart. We are experts in manufacturing custom carbon fiber parts, and everything that goes into making them. From outdoor recreation equipment to aerospace manufacturing, we’ve done it all. Our team of experts guides you through every step, from prototype to full-scale production, bringing your project to life with precision and performance.

RECREATION

MEDICAL

AEROSPACE

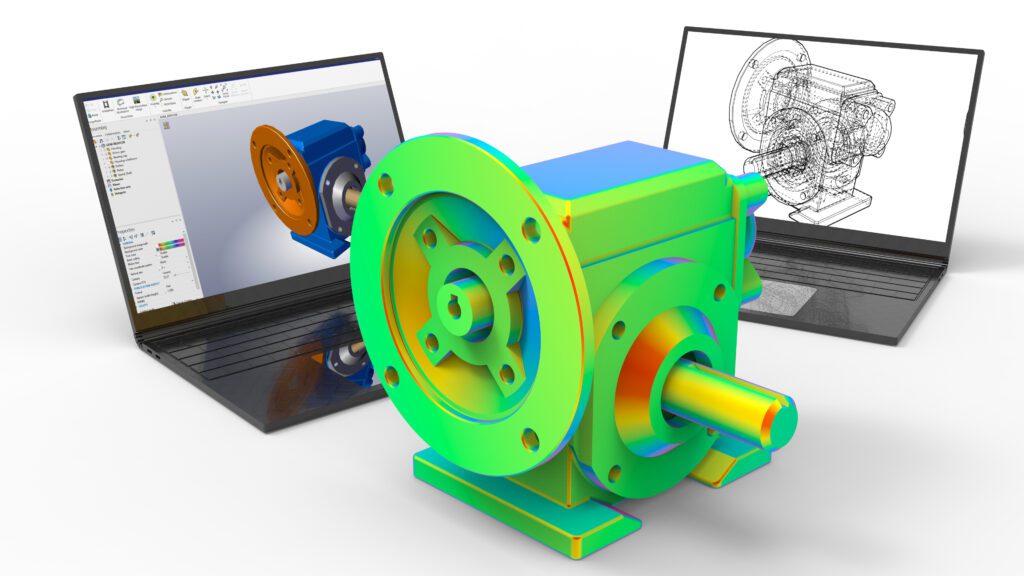

INDUSTRIAL

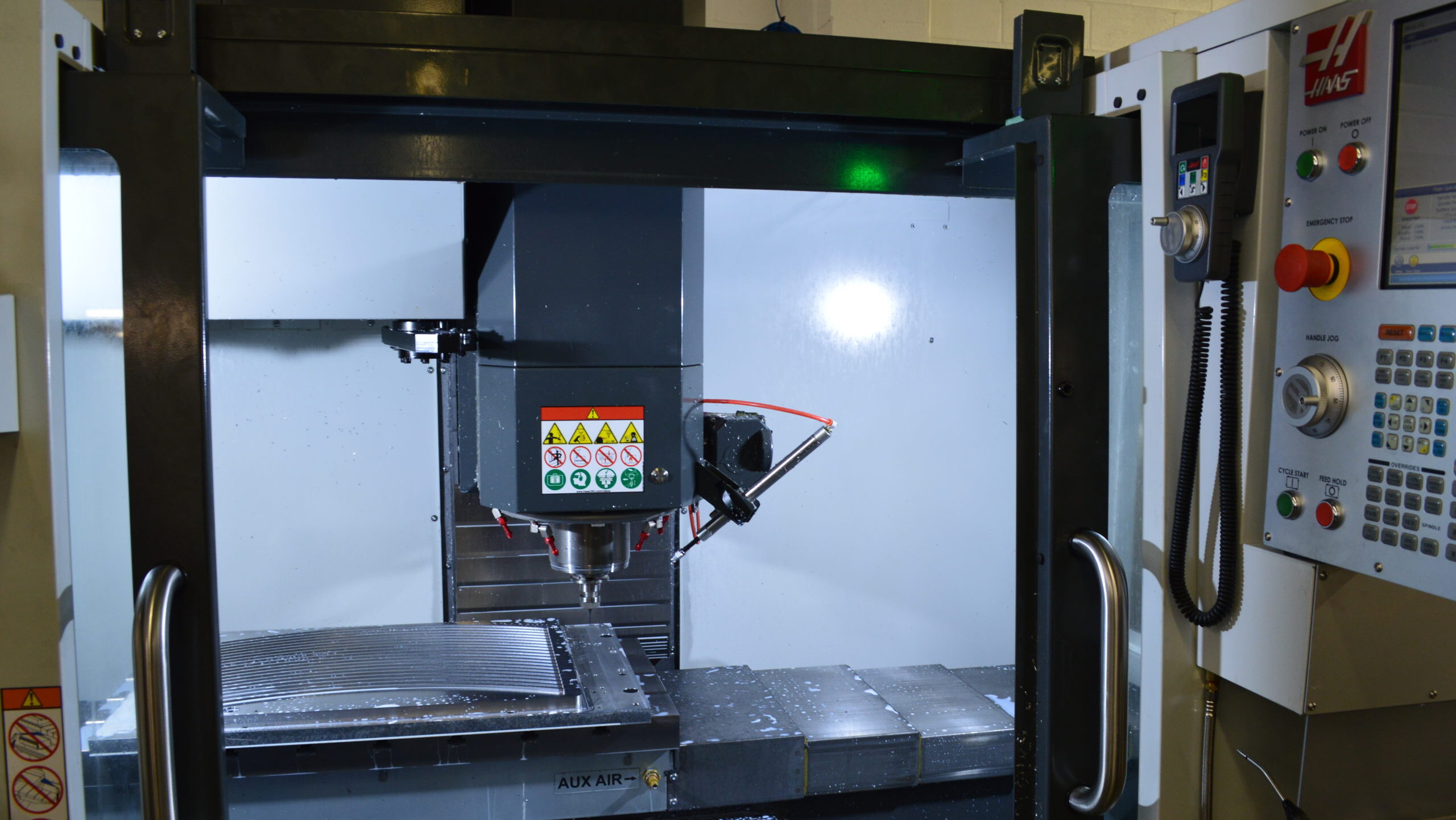

MACHINING

... AND MORE

1700 +

Projects Completed

100 +

Combined Years of Experience

1994

Year Established

10 +

Industries Served

Collaboration and Partnership

WHAT OUR CUSTOMERS ARE SAYING

AeroParts

Connie Alcala, Purchasing Manager

"AeroParts is extremely happy with the level of service, and workmanship Southwest Composite Works is providing. We look forward to this relationship continuing into the future."

Zpacks

Joe Vallesko, Founder

"We have been a happy customer since 2019. We buy carbon fiber components for a finished product that we manufacture. We've had good communication, good quality, and on time deliveries."

HIA VELO

Sam Pickman , Director of Product and Engineering

“Southwest pattern works has the best combination of professionalism, experience, quality, turnaround and price. They have won our business as tooling provider for all of our carbon fiber molds.”

choose american manufacturing

OUR VALUED PARTNERS

We’re proud to partner with customers across a wide range of industries, from national labs to paper-napkin sketches. No matter the scale or stage of your project, we know how to collaborate and bring your ideas to life.